Applications of AI-708P

Abstract: In the field of single crystal furnace equipment transformation, it is feasible to replace the Ukrainian controller with Yudian AI-708P controllers. Make full use of the functions of the AI-708P and adopt a reasonable programming method to obtain satisfactory results. The pid controller with programming functions and the temperature control circuit diagram are given in the paper. (A1-708P controller was later upgraded to A1-808P)

Keywords: equipment modification, programming, single crystal furnace, time setting

Introduction: In 1995, our company purchased a single-sulphide cadmium telluride single-crystal furnace from Ukraine. The temperature controller used in the single-crystal furnace equipment is composed of many discrete components. The circuit is complicated and has many defects, which often affects the operation of the equipment. In 1998, we decided to renovate furnace equipment and replace this Ukrainian non-standard instruments with standard instruments.

1. The selection of instruments

Through the investigation, we decided to replace the Ukrainian instrument with Yudian A1-708P or the Eurotherm 818. At that time, in the field of single crystal furnace equipment industry, the Eurotherm 818 instrument was widely used. In other words, it is no problem to replace the Ukrainian instrument with the Eurotherm 818. But the price of Europe is expensive, so we planned to use domestic instruments instead of foreign instruments.

I analyzed the performance of Yudian A1-708P and compared the performance and price of the A1-708P with Eurotherm 818. Firstly, it was doubted whether the A1-708P can meet the requirements of producing process of the cadmium telluride single crystal furnace. The mercury cadmium telluride crystal is the material which has high requirement for the infrared device. The growth process of the crystal is about 30 days, and the length of the crystal growth time is determined by the process.

The Max setting time of the A1-708P is 9999 minutes, about 7 days; the time of the Eurotherm 818 is set to 999.9 hours (minutes), about 42 days. Although the time setting of the A1-708P is less than 30 days, the A1-708P has 30 program segments. If you fully utilize the 30-segment program function, you can also meet the 30-day time requirement. In addition, the resolution of the A1-708P can reach the standard of the process.

Although the Eurotherm 818 has many features, it is expensive. The unit price of Eurotherm 818 is about 6 times higher than A1-708P which is about RMB 1200 per unit. Obviously, the performance price ratio of A1-708P is high. In 1998, Yuguang (formerly known as Yudian) was first exposed, but its popularity was not high. People lacked understanding of the field application of the A1-708P controller. At the beginning of 1998, I went to the Xiamen Yuguang Research Institute to participate an academic exchange meeting. I saw that the Yuguang Institute had a spirit of hard work. After returning to Beijing, I worked on replacing the Ukrainian instruments with A1-708P. The equipment transformation work was relatively smooth, and the task was completed soon. After years of equipment operation test, it proves that the A1-708P instrument has reliable performance and can fully meet requirements of the process of cadmium telluride single crystal furnace.

2. The control principle of cadmium telluride single crystal furnace

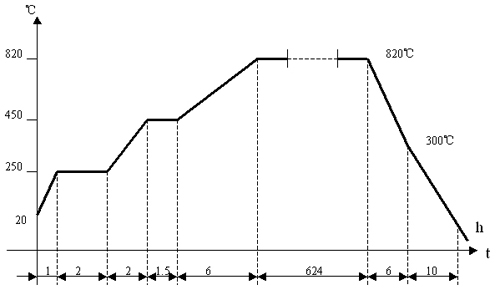

The temperature programming of the A1-708P instrument is listed below, and the temperature control circuit diagram of the single crystal furnace is attached for reference.

Table 1:

C01=20.0 starts from room temperature 20.0℃, t01=60 after 60 minutes

C02=250.0 raise to 250.0℃, t01=120 after 120 minutes

C03=250.0 keep warm at 250℃, t03=120 after 120 minutes

C04=450.0 raise to 450.0℃, t04=90 after 90 minutes

C05=450.0 keep warm at 450.0℃, t05=300 after 300 minutes

C06=820.0 raise to 820.0℃, t06=8640 after 8640 minutes

C07=820.0 keep warm at 820.0℃, t07=8640 after 8640 minutes

C08=820.0 keep warm at 820.0℃, t08=8640 after 8640 minutes

C09=820.0 keep warm at 820.0℃, t09=8640 after 8640 minutes

C10=820.0 keep warm at 820.0℃, t10=4320 after 4320 minutes

C11=820.0 keep warm at 820.0 ℃, t01=360 after 360 minutes

C12=350.0 drop to 350.0℃, t12=600 after 600 minutes

C13=20.0 drop to 20.0℃, t 13=-121 stops

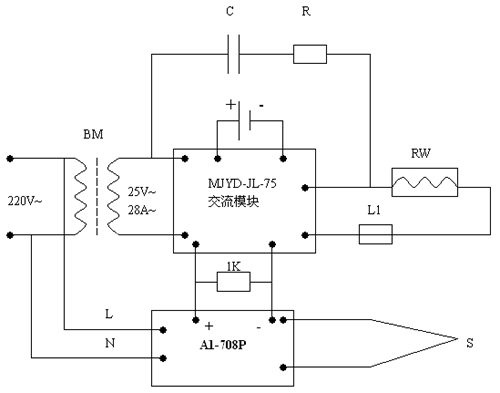

Circuit description: AC power supply is used after step-down of transformer, output voltage is 25V, output current 28A, MJYD-JL-75 is thyristor intelligent module, including thyristor and phase shift control circuit, output maximum voltage is 450V, maximum current is 75A, L1 is Overcurrent protection fuse, RC is an overvoltage protection RC component. RW is an electric furnace wire. The output of A1-708P is 0-10mA. Through 1K resistor, the output becomes 0-10V DC voltage, which satisfies the input voltage requirement of the thyristor module.

The S thermocouple is connected to the rear end of the A1-708P via a temperature compensation wire.

1. The feasible analysis of temperature control system for single crystal furnace

In the single crystal furnace temperature control system, in addition to A1-708P, there are thermocouples, compensation wires, heating furnaces, power regulators and other important components. A thorough understanding of the performance of these components is also important. Among the temperature isntruments used, the cost of economical type is about several hundreds of RMB while the universal type will take more and it is few thousands, and the basic price of each advanced instrument is several thousands RMB. If you add a few functional modules, the price can be up to tens of thousands. For a certain process, it is enough to use only one unit temperature controller that can meet the technical requirements and can operate stably and reliably. It is not necessary to use a more advanced temperature controller. It is scientific to select the type of temperature controller with a high performance-price ratio. Saving resources and making the best use of it is also the principle of selecting the type of temperature instrument.

2. Summary

Since we choosed Yudian AI-708P as the main control instrument, the cadmium telluride single crystal furnace has been working under good condition. It can completely replace the imported Eurotherm 818. Regardless of the actual operation situation or the cost of the instruments, AI-708P is the best choice.