Applications of Flow Totalizer AI-708H

Keywords: batch control, monitoring software, product data query

Overview: Qingdao Xinyutian is a professional manufacturer of polyurethane sole liquid, polyurethane resin for synthetic leather, polyester polyol and thermoplastic polyurethane resin. In order to achieve quantitative control during feeding, the quality of the product is ensured. In the production process of polyurethane resin, the automatic control scheme provided by Xiamen Yudian Automation Technology Co., Ltd., namely “AI controller + RS485 + PC monitoring software”, greatly improves the resin reaction system with good stability, operability and scalability. The practical application of the system can provide a cost-effective automatic control solution for domestic polyurethane resin manufacturers.

System composition

The whole system install one AI-708H to control the batch feed of 14 reactors. The temperature of the reactor and the current of the motor are accurately measured by 7 units of AI-704M and 7 AI-501 respectively, all of which are under control of the PC and the data is recorded and saved by the software.

Hardware: AI-708H flow totalizer, AI-704M multi-channel indicator, AI-501 single channel indicator, AI-301M open light quantity control module, RS232/RS485 converter

Software: AIFCS5.1 configuration software

Instrument selection:

Model AI-708HAI2L4S is a flow totalizer, the size is 96*96. After inserting the module, input the photoelectric isolation digital input interface for the frequency/switch type input, including 12VDC voltage output; the output is the relay large-capacity contact normally open (resistance-capacitance absorption) (265VAC/2A); with optical isolation RS485 Communication Interface.

parameter settings:

ACT=255 (the relay pull-in time is infinitely long and needs to be manually released)

FSB=? (correct the offset of the given value according to the actual situation)

SPE=750 (accumulation rate is 0.1 hours)

SN=0 (input mode is pulse frequency)

FRD=20 (upper limit of frequency signal range)

FDIP=0 (flow point)

FDIH=150 (flow range definition)

CF=0 (controller function selection)

BC=0 (no temperature and pressure compensation)

Features:

In actual application, recalibrate the flow sensor to obtain the FDIH of the meter after the flow range is obtained. The meter can accurately calculate the flow of the material according to the frequency, and close the solenoid valve according to the value set by the user to achieve accurate The batch control is blanked.

AI-704MFJ0J4V24S is a 4-channel indicator, the size is 96*48. After inserting the module, the input is 1 channel three-wire PT100 and 2 channels of current; the external band can be used for the transmitter to isolate 24V/50mA DC voltage output; with photoelectric isolation RS485 communication interface.

Parameter settings:

SN1=21 (PT100 input)

SN2=33 (current input)

DIP2=1 (1st decimal point 1st bit)

DIL2=0 (lower limit of the 2nd channel input signal range display)

DIH2=25.0 (the upper limit of the 2nd channel input signal range display)

CN=32 (number of measurement channels)

Features:

The temperature of the reaction kettle and the current of the reactor motor are uploaded to the PC, displayed on the process screen, and saved as a history.

AI-501FSV24 is a single channel intelligent indicator, the size is 96*48, for 1 channel current input. After inserting the module, the external 24V/50mA DC voltage output for the transmitter can be used; the RS485 communication interface with photoelectric isolation.

Parameter settings:

SN2=33 (current input)

DIP=1 (1 decimal place)

DIL=0 (input signal range display lower limit)

DIH=25.0 (input signal range display upper limit)

Function: The current collected in the reactor motor is uploaded to the PC, displayed on the process screen, and saved as a history.

Process requirements

1. The batch control function of the AI-708H flow totalizer can be fully operated on the computer to dose all 14 units of reactors.

2. The temperature in the bottom of the reactor and the temperature in the kettle were recorded in real time, and the reaction of the polyurethane was known according to the current of the reactor motor.

3. Record and save all data for future queries.

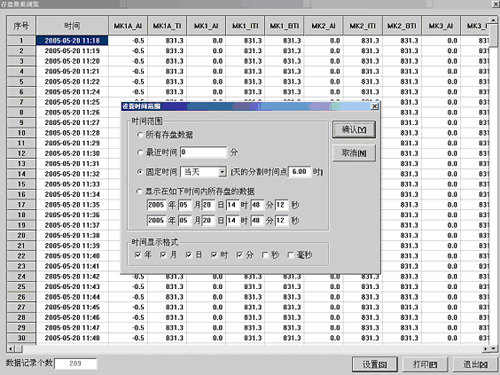

4. The real-time data provides time query, and the feed history data of the reaction kettle provides "bucket number" and "batch number" query.

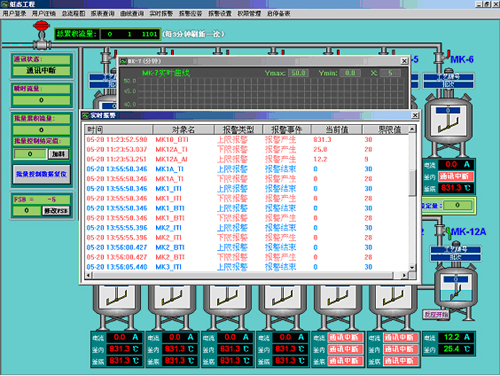

5. Provide real-time curves, real-time alarms, and alarm limit modifications.

6. Provide operating permissions and settings to prevent misuse.

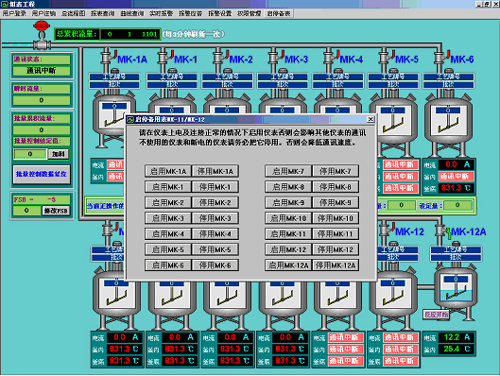

Operation Description After the software is normally logged in, the “MK-12A kettle” is taken as an example to describe in detail how to operate the AI-708H flow totalizer on the software for the quantitative control process of the kettle.

In the case where the communication status of the AI-708H meter and the communication status of the MK-12A temperature and current display value indicate "communication is normal", it indicates that the meter and the computer are connected normally.

(1) Click “Batch Control Data Reset” in the batch console on the left to clear the set value data of the AI-708H meter, and reset the feed relay to initialize the meter.

(2) Click the small valve of the red handle next to “MK-12A” to activate the kettle, and use the switch control function of the AI-301M module to open the high-pressure electric ball valve of the kettle to make the pipeline unblocked and make the valve green. There will be corresponding data display in the operation bar of the middle yellow frame. Also shown is the "Reaction Start" button.

(3) After filling in the relevant information of the tank, input the quantity to be fed in the input box under “Batch control set value”, and then click “Feed” to open the batch control relay. The feeding starts, there is an animation of the pipeline feeding. The “feed amount” will also increase correspondingly. When “bulk cumulative flow” and “batch control set value” are the same, the feeding stops, and the high-pressure electric ball valve of the kettle is automatically closed (if the error is adjusted by “FSB” during the test) .

(4) Immediately after the completion of the feeding, click “Start of Reaction”. The ACCESS database records the loading data of the current kettle and the reaction start time. The data will be displayed simultaneously on the reactor and the “End of Reaction” button will appear.

(5) If necessary, please click “Batch Control Data Reset” to clear the data of the batch control table (AI-708H), then click the small valve of MK-12A to open the high-pressure electric ball valve of the kettle, and then set “Batch Control”. Given a value", then click on "Feed". After the feeding is completed, please click the button "Feeding Record" to record the data of the re-feeding.

(6) When the current is >5A, the stirrer and the liquid level are animated, and the temperature and current data under the reaction kettle are green.

(7) Immediately after the completion of the reaction, click “End of Reaction” to record the end of the reaction so that the data curve can be queried in the future.

At this point, the production of the primary polyurethane resin of the MK-12A kettle is over.

Software Features The software provides a wide range of permissions, data processing, and query capabilities.

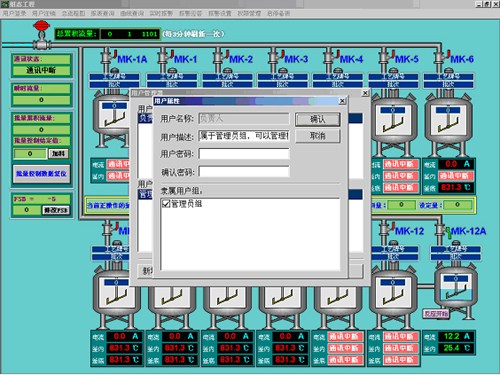

(1) "User Login" logs in again after the user logs out. (If the software is not registered, it is impossible to operate the instrument and data)

(2) The "Report Query" software database records the interval of 1 minute, and can record 1 year of data. It is divided into 5 reports, data report A, data report B, data report C, data report D and alarm report. (Data can be queried by time) as follows:

(3) "Curve query", select the corresponding kettle number, pop up as follows: enter "craft brand" and "batch" click query, you can query the corresponding curve (need to adjust the horizontal coordinate according to the actual situation, the default is 30 hours) ( The temperature in the kettle, the bottom temperature and the current are simultaneously displayed in one curve, which can be easily queried). This curve can also be used as a historical curve to query data, please click the seventh button to operate.

(4) “Real-time alarm” will pop up automatically when there is data alarm.

(5) "Alarm Response" is used to determine that this alarm message has been noticed.

(6) "Alarm Setting" is used to set the alarm limit of the data.

(7) “Permission Management” is used to modify the login password and add the loginable personnel.

(8) The “Start and Stop Table” is used to start the instrument with normal connection that needs to be used, and to disable the instrument that is not used for power failure and communication is not normal.

The production process and material status can be completely monitored and controlled by computer generated real-time curves and reports. All relevant historical data are saved in the ACCESS database, and there are complete historical reports and curves for later query.

Conclusion This system has been successfully operated in Qingdao Xinyutian Chemical Co., Ltd. for more than half a year, and the second system has also entered the commissioning phase. The on-site operation proves that the AIFCS computer monitoring system based on AI instrument and field bus is reasonable in terms of software and hardware design, reliable in operation, convenient in operation, strong in anti-interference, and greatly improves the production efficiency of polyurethane resin. Its industrial automation level has leapt to a new level.